Seamless Stainless Steel Piping

Seamless stainless steel piping, or seamless steel pipe, is formed by drawing a heated solid billet, or cylindrical bar of steel, over a piercing rod to create a hollow shell. Rollers are then used to produce the proper diameter and wall thickness. This type of stainless steel piping can withstand pressure better than welded pipe because it does not have any seams to create weak spots. It is often used in the chemical and petroleum industries.

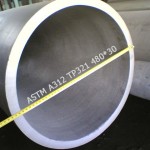

Seamless Stainless Steel Tubing under specifications ASTM / ASME / SA / A213, A249, A269, A312, A511, T304/L, T316/L, T321, T347, T410

- ASTM A213 is the standard specification for Seamless Ferritic Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes.

- ASTM A269 is the standard specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service.

- ASTM A312 is the standard specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes.

- ASTM A511 is the standard specification for Seamless Stainless Steel Mechanical Tubing.