Longitudinally Submerged Arc Welded Production Range

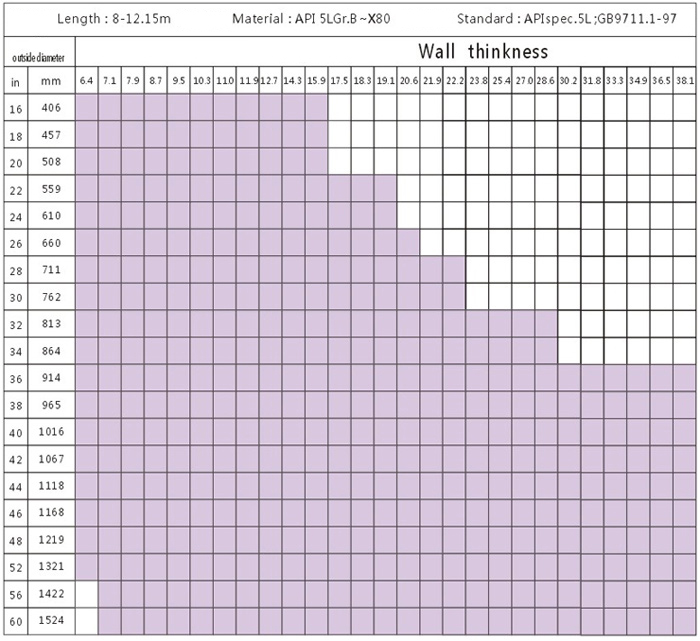

Range of LSAW pipes for oil and gas pipeline

Legnth:8-12.15m Material: API 5L Gr.B-X80, Standard: API spec. 5L; GB9711.1-97

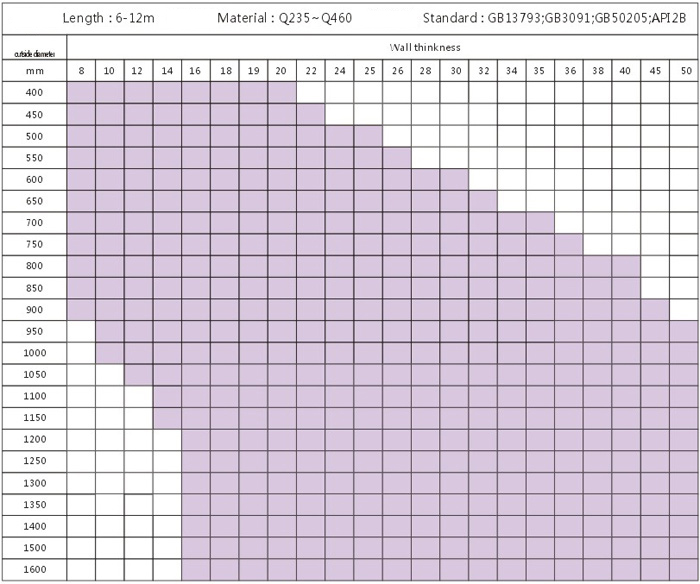

Range of LSAW pipes applied in construction

Range of roller pipes: Outer diameter: Ф1200-3800mm | Wall thickness: 12-120mm | Unit length (max) 3.2m.

- Note: The specification in the table is available to Q345.

- Remarks:non-standard dimensions pipes can be produced to customer specifications.

Range of Roller Pipes

Range of roller pipes: Outer diameter: Ф1200-3800mm | Wall thickness: 12-120mm | Unit length (max) 3.2m.| Number | Technical parameter | Unit |

HQW11s-120X3200 |

||

| 1 | Material yield limited | Mpa |

245 | 345 | 345 |

| 2 | Wall thickness | mm |

120 | 100 | 110 |

| 3 | Maximum pre-bending thickness | mm | 110 | 90 | 100 |

| 4 | Maximum width of steel plate | mm | 3200 | 3200 | 3200 |

| 5 | Minimum diameter of fully loaded rolling steel plate | mm | 2500 | 1600 | 1600 |

UOE (Uing and Oing forming) Pipes

Specifications

- Throughput: 400,000 MT

- Outside Diameter : Φ508-Φ1118mm (20"-44")

- Wall Thickness : 6.4-25.4mm (1/4"-1")

- Ouality Standards : API, BS, ASTM , JIS, DIN, GB , ISO, DNV

- Length : 9-12.2m (30'-40')

- Grades : GB/T9711 L190-L555 (API 5L A-X80)

- We are able to provide customers with quality products and perfect service.

- If you want to know more information, please kind to visit our website.

Manufacturing Process:

Manufacturing Process: