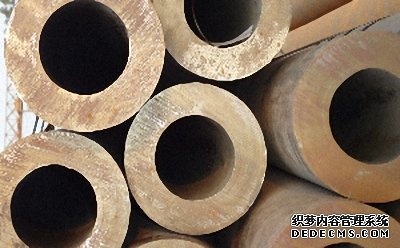

Identification method of thick-walled seamless steel pipe

TPCO

Identification method of fake thick-walled seamless pipe

8.Fake thick-walled seamless steel tube cross-section is oval, the reason is the manufacturers in order to save materials, finished roll before the two-side of the pressure is large, the strength of this type of steel is greatly reduced, but also does not meet the size of rebar profile standards. 9. High-quality thick-walled seamless steel tubes, the composition of uniform, cold shearing machine tonnage, cutting head smooth and neat, and shoddy materials due to poor material, cutting the end of the face will often have the phenomenon of meat off, that is uneven, and no metal luster.

8.Fake thick-walled seamless steel tube cross-section is oval, the reason is the manufacturers in order to save materials, finished roll before the two-side of the pressure is large, the strength of this type of steel is greatly reduced, but also does not meet the size of rebar profile standards. 9. High-quality thick-walled seamless steel tubes, the composition of uniform, cold shearing machine tonnage, cutting head smooth and neat, and shoddy materials due to poor material, cutting the end of the face will often have the phenomenon of meat off, that is uneven, and no metal luster.

And as a result of shoddy products manufacturers cut less than the head and tail will appear big Rzi. 10. Shoddy thick-walled seamless steel pipe material containing many impurities, steel density is small, and the size of the extreme difference, so in the absence of vernier caliper, it can be weighed and checked. For example, for threaded steel 20, the national standard stipulates that the maximum negative tolerance is 5%, fixed ruler 9M when its single theoretical weight of 120 kg, its minimum weight should be: the X (l-5%) = 114 kg, weighing out the actual weight of one of the smaller than 114 kg, is a shoddy thick-walled seamless steel pipe, The reason is that it has a negative tolerance of more than 5%.

In general, the effect of the whole proportionality will be better, mainly considering the problem of cumulative error and probability theory. 11. Fake thick-walled seamless steel tube size fluctuations, the reason is: l, steel temperature instability has yin and yang surface. 2, the composition of steel is uneven. 3, because the equipment is simple, the foundation strength is low, the rolling mill's bounce is big.

will appear in the same week inside the internal diameter change is larger, such a steel bar is not uniform easy to produce fracture. 12.

The trademark and printing of high-quality materials are relatively standard. 13.

Three thick-walled seamless steel pipe diameter of more than 16 of the large thread, the spacing between the two trademarks in IM above. 14.

The longitudinal rib of the inferior thick-walled seamless steel pipe is often wavy. 15. Shoddy thick-walled seamless steel tube manufacturers because there is no driving, so the packaging is relatively loose. Oval side

上一篇:3PE anti-corrosion pipeline

下一篇:Material requirements for making carbon steel pipe fittings